LCA Automation

What Is LCA Automation?

LCA automation is a method that assists companies conduct LCAs at scale. It provides real-time data on the environmental impacts and carbon emissions of the full product portfolio at a fraction of the time and cost associated with manual processes.

With LCA automation, enterprises can ensure their LCA results are consistent, comparable, and error-free. This is because LCA automation uses modeling that produces more reliable results compared to manual processes.

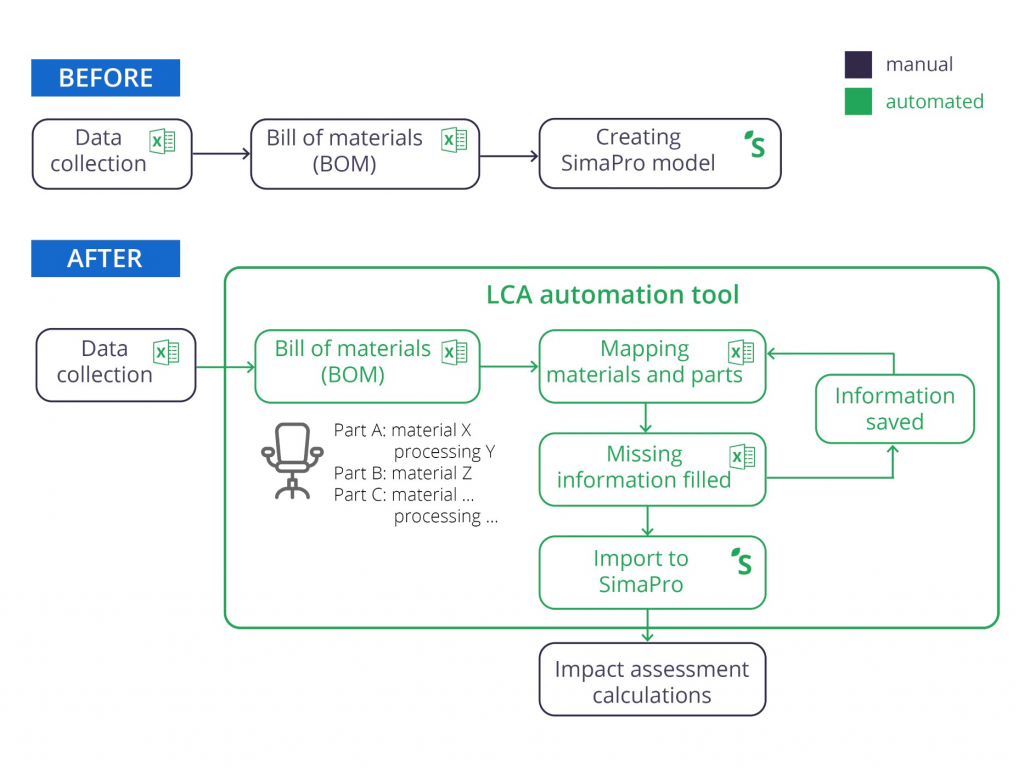

LCA Automation – way of operating.

LCA automation requires data:

- Primary data – The materials that are used to manufacture a product, the composition of the product and the resources and energy used during its production and supplier data. This data can be found on the product’s bill of materials (BOM).

- Production data – all the steps needed to manufacture a product. LCA automation software can help determine which manufacturing steps correspond to each product.

- Calculation engine that processes the data – It calculates the emissions produced and resources used in a company’s manufacturing processes. The calculation engine also processes environmental impact data. LCA automation pulls in this data automatically and performs calculations without the need for any manual entry.

Improving Product Sustainability with LCA Automation

To improve product sustainability, companies can use the automated LCA to have a better understanding of the entire life cycle and value chain of their product portfolios.

Companies have a more accurate picture of their product portfolios’ environmental impacts at a fraction of the time and cost of manual LCA processes.